Wastewater treatment online tour

Calgary has three wastewater treatment facilities:

- Fish Creek Wastewater Treatment Plant

- Pine Creek Wastewater Treatment Plant

- Bonnybrook Wastewater Treatment Plant

Together, these treatment plants meet the wastewater and sewage needs of more than one million Calgarians each day.

We invite you to take the wastewater treatment tour below.

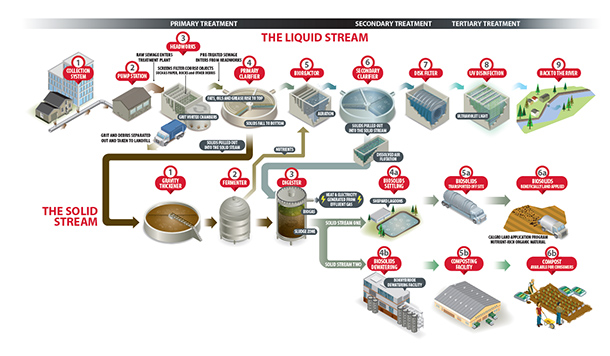

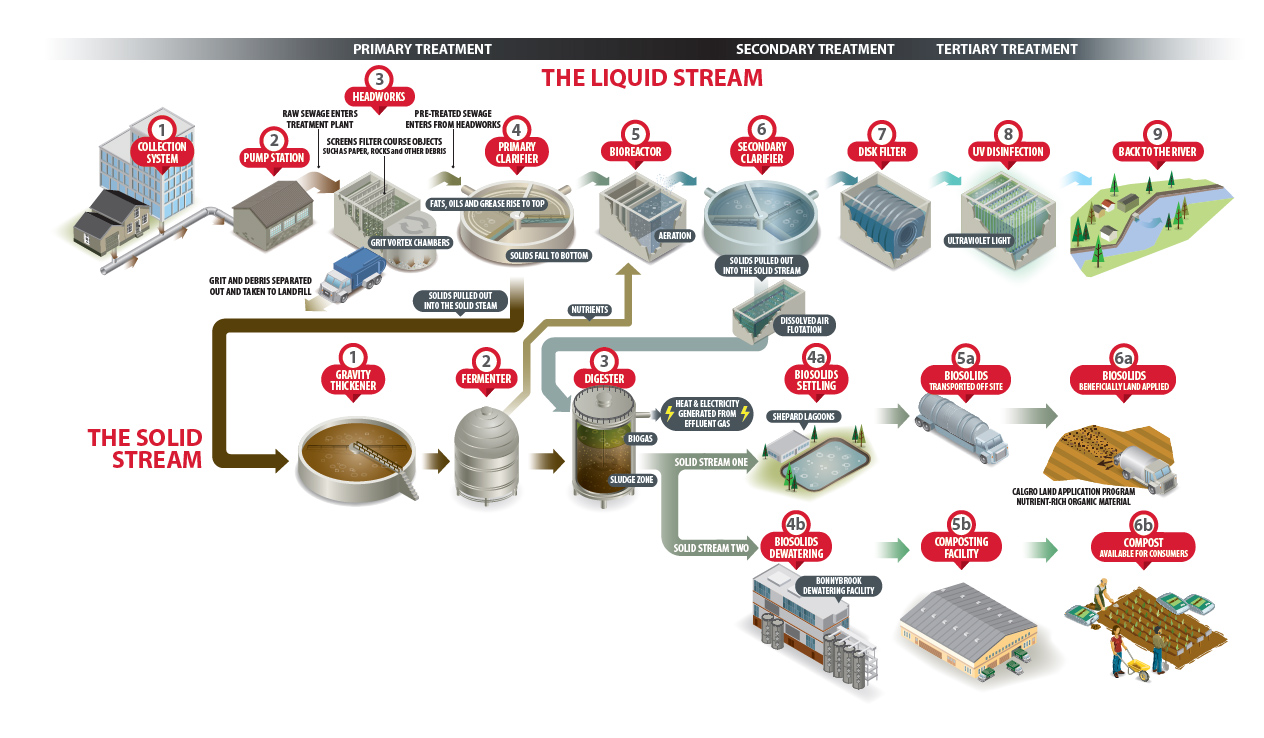

The liquid stream

Collection system

When water runs down a sink, drain or toilet, it becomes wastewater. Calgary has a system just for wastewater that moves it by gravity and pumps it to one of three treatment plants.

Pump station

Pump stations in Calgary move wastewater through the sewer system to the plants.

Headworks

Wastewater passes through screens that remove larger materials like plastic bags, wads of toilet paper, flushable wipes, and even debris like toys, sticks and tennis balls.

Wastewater then travels into grit tanks where the heavier dirt and larger solids settle to the bottom before moving through the primary clarifiers. We take these materials to one ofCalgary’s three landfills.

Primary clarifiers

Wastewater stays in these large tanks for about three hours. In that time, solids settle to the bottom becoming sludge.

Fats, oils and greases are skimmed off the top. The sludge and skimmed waste is pumped to the digesters. The overflow, called primary effluent, from these tanks is treated next in the bioreactors.

Bioreactors

These large, open-air tanks mix primary effluent with micro-organisms and air. These micro-organisms eat the dissolved nutrients, like ammonia and phosphorus and other organic material.

Having the micro-organisms eat the nutrients is a good thing otherwise these nutrients encourage plant growth in the Bow River.

An overabundance of plant life in the river will use up oxygen which fish need to live. The liquid flowing out of the bioreactors flows into the secondary clarifiers.

Secondary clarifiers

The micro-organisms settle to the bottom of these tanks as sludge. From here, some of the micro-organisms are sent back to the bioreactors to re-stock the microbe supply.

The remainder are sent to the digesters. The overflow, referred to as secondary effluent, from these tanks goes to the ultraviolet disinfection process for further treatment.

Disk filters

At some of the plants, treated water flows through cloth disk filters, improving water quality by reducing solids, phosphorus and algae before moving on to disinfection.

UV disinfection

The treated wastewater is pretty clean, but it still contains a large number of invisible, disease-causing microbes.

To make these microbes harmless all treated wastewater passes between light tubes emitting ultraviolet light.

The ultraviolet light changes the organisms’ DNA structure so they cannot reproduce. The water – now final effluent – then flows into the Bow River.

Back to the river

The water returned to the Bow River is clear, colourless, high in dissolved oxygen and very low in solids, phosphorus, ammonia and nitrogen.

Our water quality testing laboratories work seven days a week, 365 days a year. We collect samples at all stages of treatment, and ensure that water returned to the river meets standards set by the Provincial Government.

The solid stream

Gravity Thickeners

Sludge from the primary clarifiers passes to gravity thickeners for more settling.

This thickens the sludge more before it’s pumped to either the digesters or fermenters.

Fermenters

Sludge sent to the fermenters is thickened and some is used to provide nutrients for the microorganisms in the bioreactors. The remaining sludge is pumped to the digesters.

Digesters

Sludge enters warm oxygen-less digesters where, over a period of 25 days, bacteria breaks down complex organic materials into water, methane and carbon dioxide.

The methane is used as a fuel to produce heat and electricity for use at the wastewater treatment plants.

The digested sludge, called biosolids, is less smelly and many disease-causing organisms are destroyed. Biosolids are used in our Biosolids Management Program.

Biosolids Management Program

Our Biosolids Management Program recovers and recycles nutrient-rich organic matter for composting and agricultural purposes.

In the spring and summer, the biosolids go to the Shepard Lagoons to settle out for about six weeks. After settling out, the final product is a nutrient-rich resource ready for our Calgro program.

It is transported by truck to agricultural lands where it is applied using a machine called a TerraKenny. Farmers who are enrolled with our Calgro program use the organic matter and nutrients for crops such as cereal grains, trees, sod, small oilseeds and dried legumes. This program has been running for more than 30 years.

In the fall and winter months, much of the biosolids go to the de-watering facility where the water is removed.

The remaining water is eventually pumped back to the wastewater treatment process to be treated and returned to the river, and the de-watered biosolids go to the composting facility to be further processed for about 60 days, producing a high quality Category A compost.